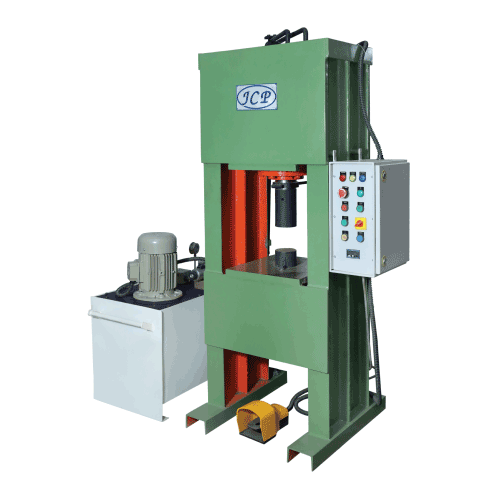

H Fix Frame Hydraulic Press

Frame

The Frame Is Of All Steel Constructed, Fabricated From Steel 2062 E-25 Grade. With Best Workmanship, Robust And Streamline Construcon Is Developed And Designed Aer Maker’s Extensive Experience In Manufacturing And Sales Of Such Machines. Thus The Accuracy Of The Machine Is Never Disturbed.

Table & Ram

Table And Slide Are Made Of High Grade Heavy Duty Cast Iron / Steel Fabricated And Properly Seasoned. They Are Perfectly Aligned, To Each Other To Obtain High Accuracy And Precession Press Operation.

Cylinder

The Cylinder Bodies Are Precisely Made From Forged Steel Material Duly Bored And Fine Honed For Long Sealing Life. The Piston Rods Are Made From EN – 8 Material Having Low Carbon Contents. The Piston Rod Is Hard Chrome Platted (200 Micron).

Hydraulic System

The Compact Blocks Eliminate The Leakage Chances And Also Reduces The Hydraulic Pipes. This Low Noise Hydraulic System Is Placed On the Rear Side of Machine, On Top between Two Side Plates. Pressure Relief Value Is Provided To Safe Guard The System And Machine From Overload. The Hydraulic System Is Driven By An Electric Motor Of Reputed Brand And Is Coupled With A Pump Capable Of Generating More Than The Required Pressure. Pressure Gauge For System Pressure, Back Pressure And Holding Pressure Are Providing On Top Of Oil Tank For Quick Reference.

Control Panel

The Electric Control Panel Is Located On The Left Hand Side Of The Machine. It Is Assembled From The Internationally Reputed Parts For Consistent Performance, Reliability And Availability, If Needed To Be Replaced. It Is Wired Cleanly And Labeled/Ferruled Properly As Per The International Practices To Help Easily Locate Any Fault And Replace Components Conveniently.

Standard Accessories

- Stroke Adjustment with Limit Switch

- Power Pack with All Hydraulic Components

- Front Operator Control Penal

- Movable Foot Switch

- Stroke Counter

Optional Accessories

- Safety Light Curtain ( Sensor )

Application

- Punching, Stamping , Forming , Embossing ,Cutting , Bending and Riveting etc

| Modal. NO. | Ton Capacity | STROKE LENGHT MAX. (MM) | NO.OF STROKE PER 1 INCH LENGHT | BED TO RAM DIST. | HOLE IN RAM | BED SIZE | H.P | OIL TANK (LITRE) | FLOOR TO BED | Approx. Wait | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| length | width | |||||||||||

| JHPHT-1 | 10 Ton | 100 | 50 | 225MM | 25MM | 455X305 | 2 | 90 | 725 APR. | 650 | Kgs | |

| JHPHT-2 | 20 Ton | 125 | 40 | 250MM | 32MM | 505X305 | 3 | 120 | 750 APR. | 1150 | Kgs | |

| JHPHT-3 | 30 Ton | 150 | 40 | 300MM | 38MM | 555X380 | 5 | 170 | 750 APR. | 1750 | Kgs | |

| JHPHT-4 | 40 Ton | 150 | 40 | 300MM | 38MM | 555X380 | 5 | 200 | 750 APR. | 2000 | Kgs | |

| JHPHT-5 | 50 Ton | 150 | 50 | 350MM | 51MM | 710X455 | 7.5 | 230 | 750 APR. | 2250 | Kgs | |

| JHPHT-6 | 60 Ton | 150 | 50 | 350MM | 51MM | 710X455 | 7.5 | 250 | 750 APR. | 2700 | Kgs | |

| JHPHT-7 | 80 Ton | 200 | 50 | 400MM | 51MM | 775X550 | 10 | 320 | 755 APR | 3250 | Kgs | |

| JHPHT-8 | 100 Ton | 200 | 50 | 450MM | 51MM | 815X585 | 15 | 400 | 755 APR | 4500 | Kgs | |

| JHPHT-9 | 150 Ton | 200 | 40 | 500MM | 63MM | 965X685 | 20 | 450 | 800 APR. | 5500 | Kgs | |