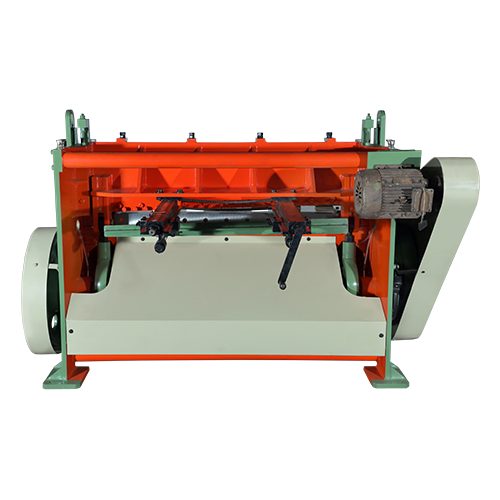

Mechanical shearing machine

Frame

The Frame Is Of All Steel Constructed, Fabricated From Steel 2062 E-25 Grade. With Best Workmanship, Robust And Streamline Construcon Is Developed And Designed Aer Maker’s Extensive Experience In Manufacturing And Sales Of Such Machines. Thus The Accuracy Of The Machine Is Never Disturbed.

Table & Ram

All M.S Plate Constructed, Fabricated From Steel 2062 E-25 Grade. The Top & Boom Blade Is Fied & True And Firm Support At Its Accurately Machined Seat. Table Is Adjustably For Seng The Blade Clearance & The Top Surface Of The Table Is Provided With T Slots For Adjusng The Front Gauge. Ram Sliding Surface Are Machined And Hand Scrapped For Smooth Travel And Sustained Accurately.

Hold On Plate

The Spring Loaded Mechanical Hold Down Plate Hold The Sheet Securely, To Avoid Slipping And Bowing Resulng In Clean Square Cuts.

Drive

Motor, Mounted On An Adjustable Plat, Drives The Large Cast Iron Fly Wheel Through V-Belts. The Power Is Further Transmied To The Fly Wheel Sha Through Steel Pinion And Main Gear Box And Than Transmied To Main Gear. Gun-Metal Bushes Are Provided All The Rotang Parts.

Clutch

The Clutch Is Of Pin/Rolling Key Type. The Clutch Is Rigid And Well Supported. The Clutch Gives Connuous Stroke For Mass Producon.

Shaft

Shaft Is Made Of Special Alloy Steel En8d / C45 Machined To Close Accuracy And Fied In Bronze Bushes For Perfect Alignment.

Flywheel

Properly Sized Flywheel Is Made Of Grade Cast Iron & Is Balanced For Storing And Releasing Adequate Energy For The Pressing Operaons.

Gears

Main Gear Is Made From (Wcb 1030). Ideal And Pinion Gear Are Made From En8-D And Pinion Gear Is Heat Treated.

Gauges

Front Gauge T-Sloed Front Gauge Fabricated From Mild Steel Is Detachable. Rear Gauge Rack And Pinion Type Rear Gauge Provides Accuracy And Is Easily Adjustable To Parallel And Taper Strips Efficiently.

Blade

Everest Shears Are Provided With High Quality Single Or Segment HCHCR Blade, With Four Edged

Standard Accessories

- Front Gauge

- Rear Gauge

- Side Squaring

- Foot Pedal

- Motor Pulley

- Oil Cups For Lubricaon Point

- Fly Wheel & Gear Guard

Oponal Accessories

- Electric Motor

- Starter

- V-Belts

- Lubricaon Pump (Hand/Motorized)

- Front Gauge, Rear Gauge With Scale

- Pneumac Pedal

- Digital Stroke Counter

- Pneumac, Mechanical & Servo Feeder & De – Coiler & Straightener

Power Supply

400/440 Volts, 3 Phase, 50 Cycles.

Note

Electric Items & Blades & Spring Are Not Under Warranty.

Machines Will Be Supplied Without Electrical & V-Belts.

| MODEL | CUTTING CAPACITY IN M.S. | FRONT GAUGE | REAR GAUGE | FLOOR TO TOP TABLE | TABLE WIDTH | BLADE SIZE | STOKE PER MINUTE | HOLD DOWN TO KNIFE EDGE | MACHINE(LXWXH) | MACHINE MOTOR | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (LXT) | (LXWXT) | LENGTH | WIDTH | HEIGHT | H.P/KW | |||||||

| JUS-1 | 610X1.5 | 450 | 450 | 875 | 292 | 635X62X14 | 70 | 5 | 1200 | 1000 | 1100 | 1/0.750 |

| JUS-2 | 914X.5 | 450 | 450 | 875 | 292 | 940X62X14 | 70 | 7 | 1500 | 1000 | 1100 | 1/0.750 |

| JUS-3 | 1270X1.5 | 500 | 450 | 900 | 318 | 1295X62X14 | 65 | 9 | 1900 | 1100 | 1200 | 2/1.5 |

| JUS-4 | 1525X1.5 | 500 | 450 | 900 | 318 | 1550X62X14 | 65 | 6 | 2200 | 1200 | 1200 | 2/1.5 |

| JUS-5 | 2030X1.5 | 500 | 600 | 900 | 330 | 2057X62X14 | 60 | 7 | 2750 | 1250 | 1200 | 3/2.2 |

| MODEL | CUTTING CAPACITY IN M.S. | FRONT GAUGE | REAR GAUGE | FLOOR TO TOP TABLE | TABLE WIDTH | BLADE SIZE | STOKE PER MINUTE | HOLD DOWN TO KNIFE EDGE | MACHINE(LXWXH) | MACHINE MOTOR | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (LXT) | (LXWXT) | LENGTH | WIDTH | HEIGHT | H.P/KW | |||||||

| JUS-6 | 610X2 | 600 | 600 | 800 | 355 | 635X62X14 | 65 | 3 | 1470 | 1000 | 1300 | 2/1.5 |

| JUS-7 | 914X2 | 600 | 600 | 800 | 355 | 940X62X14 | 65 | 4 | 1770 | 1000 | 1300 | 2/1.5 |

| JUS-8 | 1270X2 | 600 | 600 | 800 | 355 | 1295X62X14 | 60 | 6 | 2200 | 1200 | 1300 | 3/2.2 |

| JUS-9 | 1525X2 | 600 | 600 | 800 | 355 | 1550X62X14 | 60 | 7 | 2450 | 1200 | 1300 | 3/2.2 |

| JUS-10 | 2030X2 | 600 | 600 | 825 | 400 | 2057X62X14 | 55 | 9 | 3000 | 1300 | 1400 | 5/3.7 |

| JUS-11 | 2540X2 | 600 | 600 | 825 | 400 | 2550X62X14 | 55 | 11 | 3500 | 1300 | 1400 | 5/3.7 |

| JUS-12 | 610X4 | 600 | 600 | 800 | 400 | 635X75X18 | 60 | 3 | 1470 | 1200 | 1300 | 3/2.2 |

| JUS-13 | 914X4 | 600 | 600 | 800 | 400 | 940X75X18 | 60 | 4 | 1770 | 1200 | 1300 | 3/2.2 |

| JUS-14 | 1270X4 | 600 | 600 | 825 | 400 | 1295X75X18 | 55 | 6 | 2350 | 1300 | 1400 | 5/3.7 |

| JUS-15 | 1525X4 | 600 | 600 | 825 | 400 | 1550X75X18 | 50 | 7 | 2550 | 1300 | 1400 | 5/3.7 |

| JUS-16 | 2030X4 | 600 | 600 | 825 | 455 | 2032X75X18 | 50 | 9 | 3150 | 1400 | 1500 | 7.5/5.6 |

| JUS-18 | 2540X4 | 600 | 600 | 825 | 455 | 2550X75X18 | 48 | 11 | 3600 | 1400 | 1500 | 7.5/5.6 |